Features

Features

- 5 frame sizes, multiple lengths

- 230 / 400 / 480 VAC windings available (high and low)

- 4.5 to 510 N-m (3.3 lb-ft to 376 lb-ft) continuous torque accommodates a wide range of high-power application requirements

- Speeds up to 2,500 rpm meet most medium speed and high torque application requirements

- Power ratings from 775 to 11,700 watts meet high power demands for most applications

- Integral sine encoder feedback provides resolution of over 134 million counts per revolution

- Built-in thermistor provides over-temperature protection

- UL Listed for global acceptance

Benefits

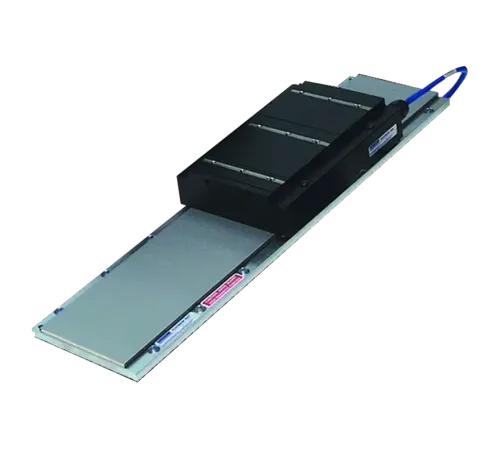

- Provides the space-saving and performance advantages of a frameless DDR motor with the ease of installation of a full-frame motor

- Integrated compression coupling and shipping hardware: eliminates parts and labor for a faster, lower-cost machine build

- Installs in 5 minutes

- Up to 50% more torque density than comparably sized conventional servo motors

- Direct load connection eliminates backlash, compliance and maintenance of gearboxes, belts or pulleys

- Low cogging for smooth low-speed rotation

- Zero backlash and compliance provides more responsive system performance

- Pre-configured amplifiers and feedback devices simplify installation and startup

Specifications

| C04x, C05x, C06x | C09x, C13x | |

|---|---|---|

| Coupling Technology | Single bolt split hub, access front motor | Multi-bolt compression, access from rear of motor |

| Mounting Requirements Shaft TIR | .005" (.13 mm) | 0015" (.038 mm |

| Perpendicularity of Machine Mounting Face | 004" (.10 mm) | 002" (.051 mm) |

| Concentricity of Machine Pilot to Shaft | .004" (.10 mm | .002" (.051 mm |

| Shipping Hardware | Alignment bolt and cap screw | 4 set screws and 4 shipping bolts |

| Mounting Procedure | Procedure # M-RT-S19-0 | Procedure # M-RT-019-07 |

Inquiry - Cartridge DDR